Join the Leaders: Automation Can Transform Your Pallet Manufacturing

For small and medium-sized producers of wooden pallets, the daily grind often involves a significant reliance on manual labor for nailing. While this approach might seem familiar, it can present limitations in terms of production speed, consistency, and overall cost-effectiveness. However, by strategically investing in new machinery and automation for pallet nailing, these producers can unlock significant benefits that lead to long-term profitability and growth.

Why Now is the Time to Consider Automated Nailing:

The landscape of manufacturing is constantly evolving, and the demand for consistent, high-quality wooden pallets remains strong across various industries. To effectively compete and scale your business, it’s crucial to explore solutions that move beyond purely manual processes. Upgrading your pallet nailing system through the acquisition of automated machinery is a pivotal step in this direction.

The Compelling Case for Mid-Term Profitability:

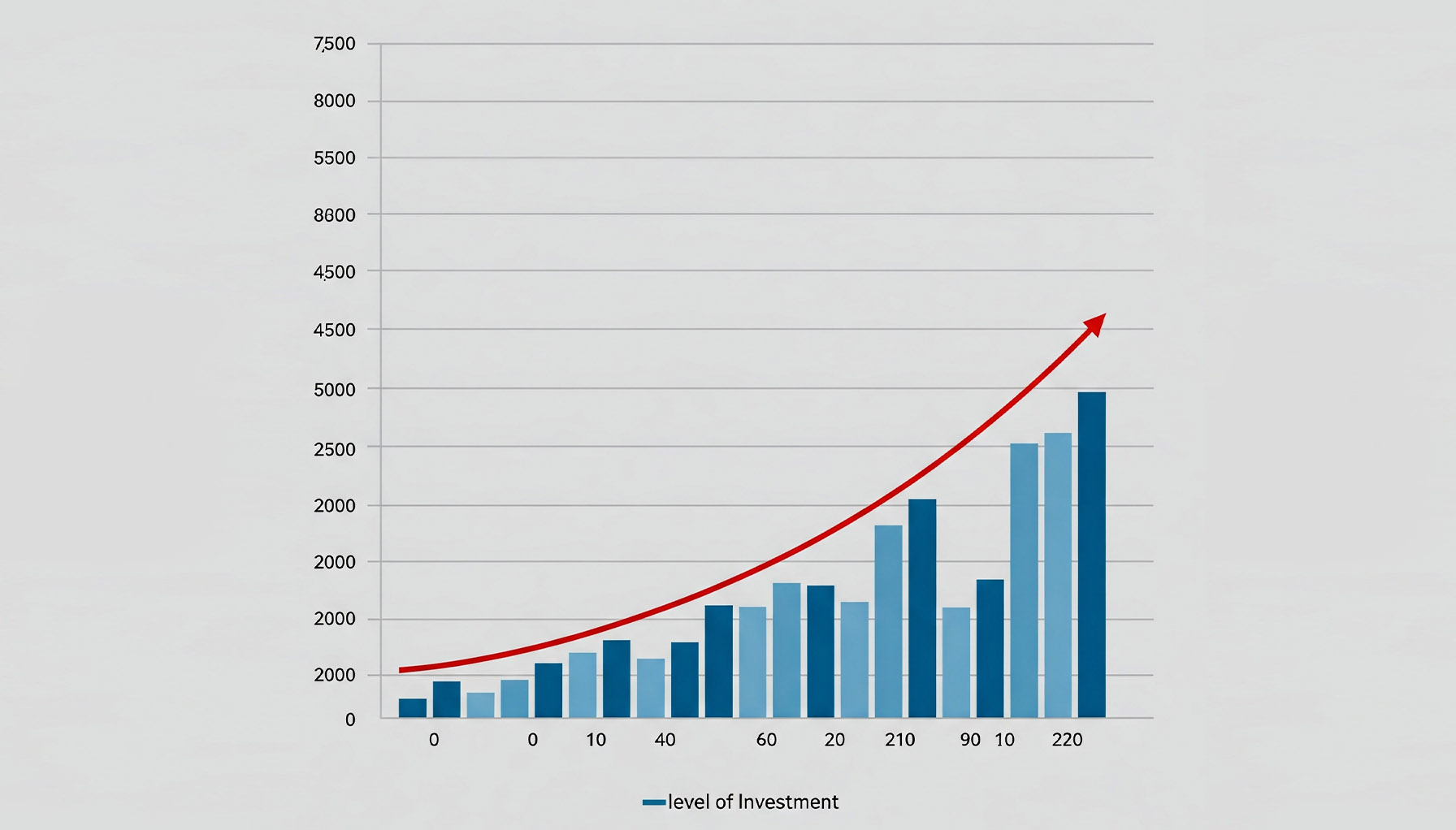

The initial investment in automated pallet nailing equipment might seem substantial. However, when viewed through a mid-term lens, the returns become increasingly clear. The primary driver of this profitability is the reduced dependence on manual labor to achieve production targets.

- Reduced Labor Costs: Automated systems require fewer operators to achieve the same, or often significantly higher, output compared to manual nailing. This directly translates to lower wage expenses, reduced overhead associated with a larger workforce, and less strain on your human resources.

- Increased Production Speed: Machines work at a consistent and often much faster pace than individuals. This allows you to fulfill orders more quickly, take on larger projects, and ultimately increase your revenue potential.

- Consistent Output: Unlike manual processes that can be subject to variations in speed and efficiency due to fatigue or individual differences, automated systems maintain a steady rate of production throughout the workday.

Elevating Quality Through Automation:

Beyond just speed and cost, automated pallet nailing significantly improves the quality and consistency of your final product.

- Standardized Nailing Patterns: Automated machines ensure that nails are placed in precise locations and at consistent depths every time. This eliminates the inconsistencies that can occur with manual nailing, leading to stronger, more durable, and more reliable pallets.

- Reduced Errors and Waste: Human error is inevitable in manual processes. Automated systems minimize the chances of misaligned nails, missed nails, or damage to the wood, reducing material waste and the need for rework.

- Meeting Stringent Standards: In many industries, pallets must adhere to specific quality and dimensional standards. Automated nailing makes it easier to consistently meet these requirements, ensuring customer satisfaction and opening doors to a wider range of clients.

The Tangible Economic Benefits of Investing:

The advantages of automated pallet nailing translate directly into economic benefits for your business:

- Lower Unit Production Costs: By reducing labor and material waste while increasing output, the cost to produce each pallet decreases, improving your profit margins.

- Increased Throughput and Revenue: The ability to produce more pallets in a shorter amount of time allows you to fulfill more orders and generate higher revenues.

- Improved Customer Satisfaction and Retention: Consistent quality and timely delivery lead to happier customers who are more likely to return for future business.

- Enhanced Competitiveness: By operating more efficiently and producing higher-quality pallets, you become more competitive in the market, allowing you to attract new customers and potentially command better pricing.

Following the Path of Industry Leaders:

Consider the trajectory of large-scale pallet producers. Virtually all of them have embraced automation as a fundamental aspect of their operations. They recognized early on that relying solely on manual labor would limit their growth potential, their ability to maintain consistent quality at scale, and their overall profitability. These industry leaders didn’t start as massive corporations; they grew by making strategic investments in technologies like automated nailing systems. By adopting similar strategies, small and medium-sized producers can position themselves for similar growth and success in the long run.

Making the Smart Move for Your Future:

Investing in automated pallet nailing machinery is not just an expense; it’s a strategic move that lays the foundation for a more efficient, profitable, and sustainable future for your business. By reducing your reliance on manual labor, improving the quality of your pallets, and increasing your production capacity, you can enhance your competitiveness, attract more customers, and ultimately achieve significant economic benefits. Take the step towards modernizing your operations and join the ranks of successful pallet producers who understand the power of automation. The time to upgrade your pallet game is now.