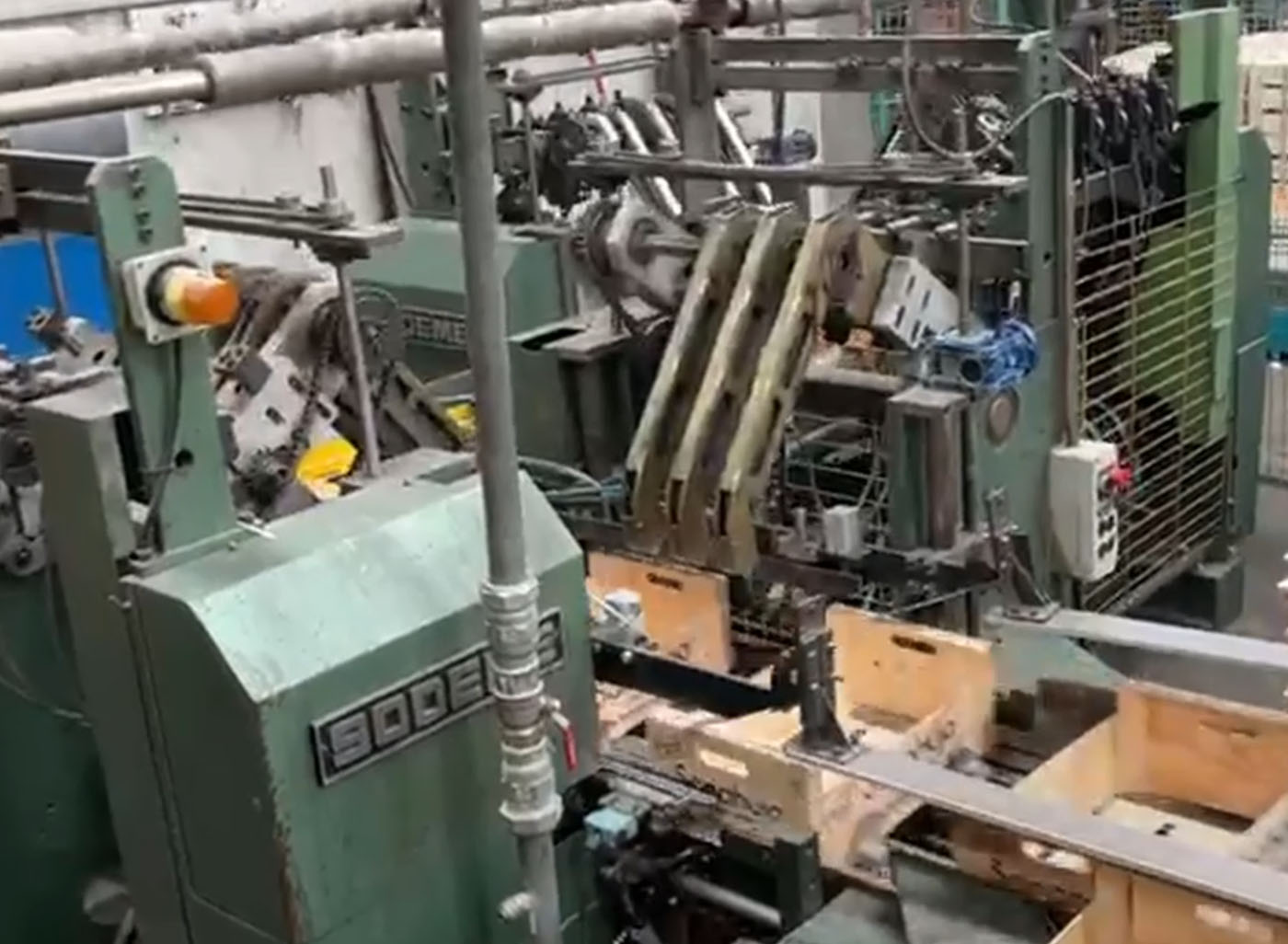

This example facility shows a machines and devices combination used to automatic assemble wooden crates.

The line is able to produce continuously between 2700 and 3200 units per hour, depending on the height of the box to be sewn. This line is complemented by a plywood sheet marking machine and a bottom stitching machine, which we also could offer.

The line shown in the video is made up of second-hand machines and devices from various manufacturers, showing that these systems offer very interesting production and profitability for some customers. We also offer the possibility of refurbishing/Tune-up this type of machinery, offering a “like new” machine at a reduced price.

The line is composed by:

- Taco cutter saw

- Taco splitter

- sheet feeder 1

- Corner stitcher heads group 1

- Corner stitcher heads group 2

- Handle drilling machine

- Slat feeder

- Slat stitcher group

- Side diverter

- Sheet feeder 2

- frame stitcher group

- Bottoms Feeder

- Bottoms stitcher group 1

- Bottom stitcher group 2

- strapping group

- Stacker robot

Visit the video for better understanding of the operation and funcionality.

To check the availability of any system similar to the one shown, please contact us.